vickers hardness test measurement|vickers hardness chart : store It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A diamond in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a Brinell impression . webMy Authenticator app or SMS two-factor authentication (2FA) has locked me out of my account; Why did I receive a two-factor sign-in code from Epic Games? Two-factor .

{plog:ftitle_list}

Want to play ZOOM-BE 2? Play this game online for free on .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A diamond in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a Brinell impression .

How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our . Due to its scaling, the Vickers hardness test is ideal for testing hard materials like steel as well as softer materials like plastic. All in all, the Vickers test has one of the widest hardness ranges among the 4 test procedures.The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers Hardness (HV) measurement method is preferred for assessing the hardness of dissimilar FSW joints due to its reliability. For dissimilar weldments, the reported hardness .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds .

In general, it should be measured with the highest possible test force, in order to minimise potential influencing factors that could distort the measurement result. To the applications & .

The Vickers hardness test can be applied for micro-testing. Knoop: Specifically used to test thin or brittle materials, as it gives a meaningful reading with a shallow indentation. It uses an elongated pyramid to make the .

Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.Hardness tests that measure the depth of indenter penetration include: Rockwell, Instrumented Indentation Testing, and Ball Indentation Hardness . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.

for the Vickers hardness testing process did not measure up to the accuracy resulting from the manual procedure (st andard de viation of 11.32 against 5.04, respectively). Thus, in the nearThe 3842 Vickers Hardness Tester is engineered to produce a clear indentation and a more precise measurement. By means of a load cell, closed circuit system for control, the CPU controls testing force to . The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the . Microhardness: The Vickers test can be used to measure the hardness of small or thin samples, making it ideal for microhardness testing. Applications of Vickers Hardness Testing Quality Control: Vickers hardness testing is extensively used in quality control and material certification processes, ensuring that materials meet specified hardness . In the Vickers hardness measurement, the combined uncertainty associated with the hardness value takes into account the relative uncertainties of diagonal length (d), the test force values (F) and other parameters like uncertainties in the indenter geometry, the indentation measuring system, etc., which are accounted in the CMC of the machine .

The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the understanding of these methods are comprehensively reviewed and discussed. Basic equations and parameters .

Automated Vickers hardness measurement using convolutional neural networks Yukimi Tanaka1 & Yutaka Seino1 & Koichiro Hattori1 Received: 1 April 2020 /Accepted: 7 July 2020 . Vickers hardness testing is often applied to metals but can be used to test other materials, including ceramics and aniso-tropic materials [9]. Typical image processing .The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.

The Vickers hardness test can measure a wide range of hardness values, from very soft materials to extremely hard ones. This makes it suitable for testing materials with a wide range of mechanical properties, including those used in aerospace, automotive, and construction industries. 6. Microhardness TestingThe Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring the

Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United .According to DIN EN ISO 6507-1, the result of a Vickers test is given as follows: 700 HV 10 / 20 ⇒ Hardness value as per Vickers . 700 HV 10 / 20 ⇒ Abbreviation for Vickers hardness . 700 HV 10 / 20 ⇒ Test force specification: Test force [N] = 9.807 * test force specification Vickers Hardness Test. The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. The specimen is first lifted until it comes into contact with the indenter.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work. Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force . The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Nano hardness measurement involves measuring the indentation depth and then calculating the contact area using an empirical formula, whereas traditional hardness measurement involves obtaining the surface area of the .The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).The general principle of the Vickers hardness test, defined by ASTM E-384, is based on an optical measurement system. The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps.choice of hardness in the various Vickers IF equations. The usual convention in the hardness community, and the one that is adopted in every formal hardness standard in the world, is to define Vickers hardness (HV) as the load divided by the contact area of the four faces of the indentation. This leads to the standard definition: (4)

The two measurements are converted into a Vickers hardness (H V) value using the following equation: H V = 0.1891 * {F[N] / d1[mm] * d2[mm]} Sample Preparation. For a high-accuracy measurement, the test should be performed on a flat specimen with a polished or prepared surface. The quality of the required surface is dependent on the force used.PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and .

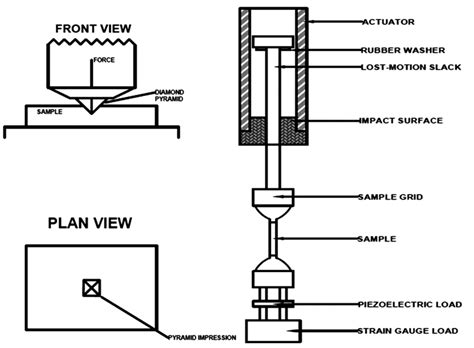

vickers hardness testing machine diagram

vickers hardness test procedure pdf

Resultado da 1 de fev. de 2024 · Claro Combo: contrate planos com TV, Internet e Celular. Busque planos do seu endereço: buscar planos. Home. planos. 2 .

vickers hardness test measurement|vickers hardness chart